Primary crushers and granulator crushers

OM Siderurgica crushers boast of a solid and estremely strong construction and are suitable for the primary and secondary crushing of any type of material. Their reliability, the high output and reduced maintainance operation guarantee very high performances. Moreover OM Siderurgica offers a wide range of granulating crushers, ideal to satisfy all requirements concerning secondary crushing. Teams of engineers and specialists will be at your disposal to modify and improve the machines in accordance with your specific requirements, guaranteeing in any case the usual quality and security.

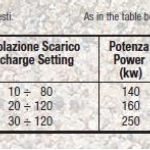

Hydraulic security system impact mills

OM Siderurgica designs and constructs primary and secondary hydraulic impact mills under banner of strength and reliability, thanks to the fixed and mobile part over-dimensioning, to the rational design of the components and the use of special high quality anti wear alloys. Moreover a pratical and easy hydraulic security system allows the structure safeguard. A wide range of models and the possibility to fit the machineries to the specific customer requirements guarantee to cover all the productivities and stone typologies.

|

Modelli |

Dimensioni Bocca |

Regolazione Scarico |

Potenza |

Peso |

Produzione |

|

MM 800 |

800 X 600 |

10 ÷ 80 |

140 |

9500 |

20 ÷ 190 |

|

MM 1110 |

110 X 750 |

20 ÷ 120 |

160 |

11000 |

30 ÷ 250 |

|

MM 1213 |

1250 X 900 |

30 ÷ 120 |

250 |

15000 |

80 ÷ 400 |

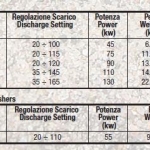

Hydraulic security system crushers

These machines are important for the primary crushing. A wide production, together with the possibility to fit the machineries to match customer’s needs, allows to OM Siderurgica to satisfy all customer requirements.

OM Siderurgica uses high quality components and special wear resistant steel to assure to the customer the maximum quality and reliability. These crushers are equipped with a hydraulic gearcase, that controls the opening of the jaws in order to obtain the granulate curve required. Furthermore a pratical and easy hydraulic security system allows the structure and jaw safeguard. OM Siderurgica offers also a wide range of granulating crushers, particularly useful for the secondary crushing.

| Frantoi primari – Primary crushers | |||||

|

Modelli |

Dimensioni Bocca |

Regolazione Scarico |

Potenza |

Peso |

Produzione |

|

FP I 75 |

750 X 500 |

20 ÷ 100 |

45 |

6000 |

10 ÷ 70 |

|

FP I 105 |

1000 X 600 |

20 ÷ 115 |

75 |

11200 |

20 ÷ 150 |

|

FP I 97 |

900 X 700 |

20 ÷ 120 |

90 |

13000 |

30 ÷ 200 |

|

FP I 106 |

1050 X 600 |

35 ÷ 145 |

110 |

14600 |

35 ÷ 240 |

|

FP I 107 |

1070 X 750 |

35 ÷ 165 |

130 |

22000 |

45 ÷ 560 |

| Frantoi secondari – Secondary crushers | |||||

|

Modelli |

Dimensioni Bocca |

Regolazione Scarico |

Potenza |

Peso |

Produzione |

|

FG 105 |

1000 X 500 |

20 ÷ 110 |

55 |

9000 |

30 ÷ 180 |

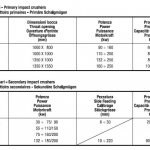

Primary and secondary impact crushers

OM Siderurgica primary and secondary crushers stand out for a strength and reliability construction, obtained thanks to the over-dimensioning of fixed and mobile parts, the rational design of the parts and the use of special high quality anti wear alloys. Thanks to this design OM Siderurgica guarantees to the final customer the desidered output. Projecting on specific customer requirements allows to OM Siderurgica to satisfy all you needs, guaranteeing usual quality and safety.

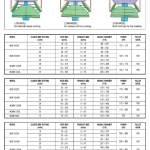

Cone crusher