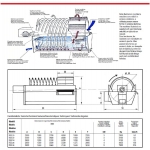

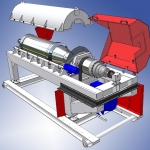

SST Drum deslimers

Machine designed for energetic, total washing of aggregates having impurities which cannot be otherwise removed. The “mixing” and conveying action of material take place by means of a series of appropriately directed blades and draining buckets located on the discharge side. Water flow is in “countercurrent” in relation to the material flow. The quantity of water required ranges from 500 to 1000 It/m3 of aggregates to be treated.

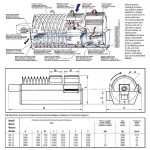

RSS Simple machine for draining and recovery

Simple functioning, study, efficient and economic to run. A partly immersed 4 thread screw conveyor drags the fine sand fallen to the bottom of the machine towards the draining wheel. The wheel recovers, drains then discharges the sand. The sand obtained is pure and ready for use. The machines are equipped with a compact, accessible epicycloidal reducer. The machine parts have been specifically planned to assure long life and minimum maintenance.

RSL Machine for recovery, draining and cleaning

Suitable for excessively impure sand. Features identical to Mod. RSS. It is equipped with two wheels, the first draining wheel collects the sand in counter-current washing (first wash) then conveys it into a second tank where a second wheel immersed in clean water effects the second (final) wash.

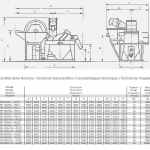

Hydrocyclone + Bucketwheel recoverer MRS/RS

OM Siderurgica proposes a machine that puts together an hydrocyclone, ideal for a complete finest grains recovery, and a bucketwheel recoverer to optimize the hydrocyclone efficiency, lightening its working load and reducing its wear. This machine guarantees a high quality and an excellent output.

MRS Sand recovery module with Hidrocyclone

The currents norms concerning concretes, require sands of a special granulometry, which is obtained only through a complete recovery of the finest grains. The hydrocyclone module is able to fulfill this difficult task as its structure respects the special and sophisticated constructive technologies. The sand recovery module with hydrocyclone, proposed by OM Siderurgica, has placed itself as a leader in its specific sector.

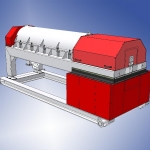

Centrifuges MD model

OM Siderurgica uses MD centrifuges, to allow a maximum fine’s recovery. This is the case of muds composed by limes with <75 granulometry. Thanks to the force centrifuge used as separator system, OM Siderurgica obtains an economically acceptable dehydration. MD centrifuges will be designed and realized exclusively to treat muds coming from stone washing. So OM Siderurgica offers centrifuges with an excellent quality/price ratio.